Industrial Valve Modification Services

Meet deadlines with confidence

At Kirksey, our company culture and responsive team of experts allow us to expedite orders and meet tight deadlines with reliable solutions. We offer a comprehensive range of valve modification services for both cast steel and forged steel, ensuring the highest standards of quality and efficiency.

Quick Links

Get Started

713-682-6704

Industrial Valve Modification Services

Valve Modifications

Cast Steel

We excel in cast steel modifications due to our extensive experience and commitment to precision. Our services include:

- Trim Changes: 316 SS, Monel, A-20, HF, Bronze, Hastelloy C

- End Conversions: RTJ from RF, RF from RTJ, Flat Face, Machine Weld End to Smaller Schedule, Build Up Bore to Larger Schedule, Modify Flanged to BW Ends

- Extended Bonnets: Cryogenic Gas Column

- Drill & Tap Body & Bonnet: By-Pass Installation, Handwheel Extensions

- Other Services: Globes to Stop Checks, Soft Disc Inserts, Gear Operator Supply and Mounting, Outside Lever & Weight, Bleed & Vent Holes, Packing & Gasket Changes, NACE, Oxygen & Chlorine Cleaning

Valve Modifications

Forged Steel (API 602)

Our expertise in forged steel modifications ensures high-performance and durability. Our services include:

- Trim Changes: 316 SS, HF, Monel, A-20, Hastelloy C

- Valve Conversions: Globes to Piston Checks, Globes to Ball Checks, Gates to Swing Checks, Piston Checks to Ball Checks

- End Conversions: Threaded to Socket Weld, Extended Body (O-Let) to Male SW or Male Thread, Male Thread from Male SW, Reduce Valve Size (Make full Port), Extended Bonnets (Cryogenic Gas Columns), Deep Stuffing Box, Packing & Gasket Changes, Soft Disc Inserts, Bolted to Welded Bonnet, Welding on Flanges – Class 150 – 1500, Buttweld end from Threaded, SW, or Flanged, RTJ from RF, RF from RTJ, Flat Face

- Other Services: NACE, Oxygen & Chlorine Cleaning

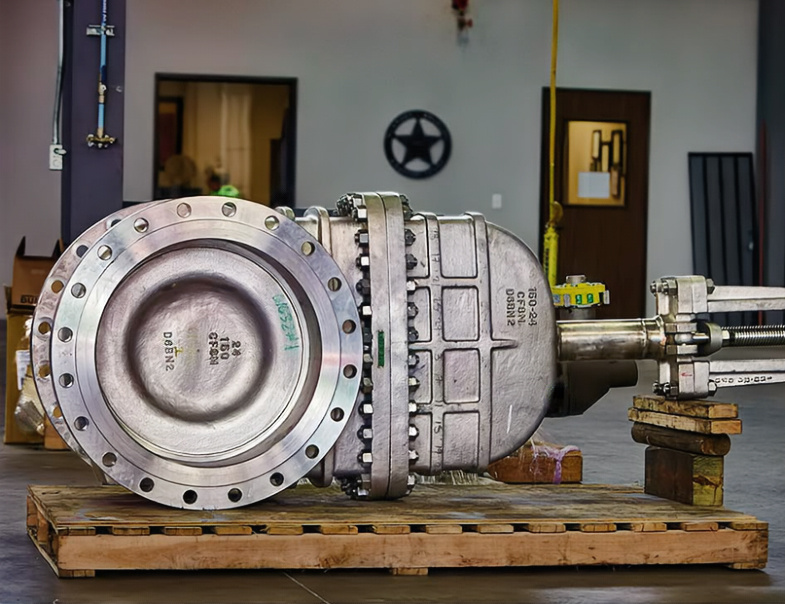

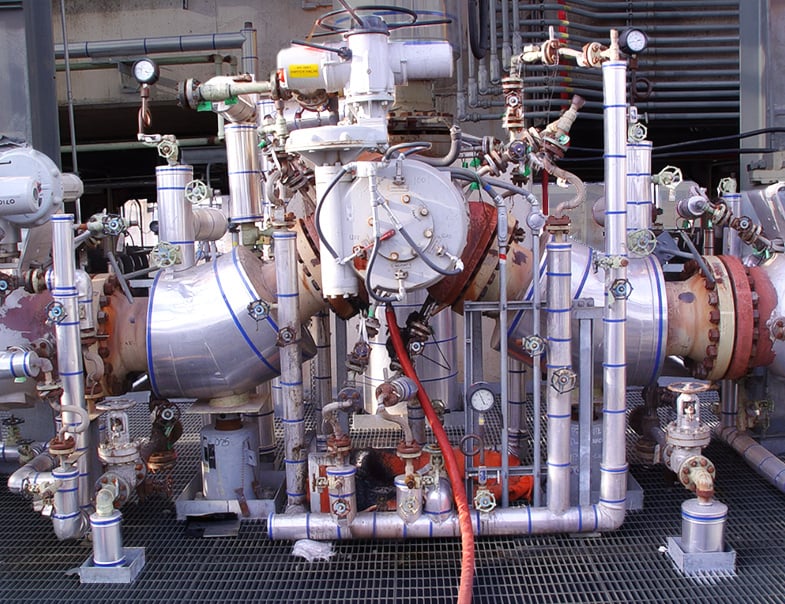

A successfully modified butterfly valve by adding a gear extension. This custom solution allows for seamless operation from a higher position, demonstrating our ability to help solve complex challenges.

A successfully modified butterfly valve by adding a gear extension. This custom solution allows for seamless operation from a higher position, demonstrating our ability to help solve complex challenges.

Why Choose Kirksey?

Many of our team members began their careers on the shop floor, mastering the machines and techniques before advancing to management roles. This deep, practical knowledge ensures that we understand the urgency of your needs and can provide immediate, reliable solutions. While other companies may offer machinists, we offer comprehensive expertise—with CONFIDENCE in every step.

About Us